Single layer product specifications: ZL1836, ZL1848, ZL1861, ZL2436, ZL2448, ZL2461, ZL3048,

ZL3061, ZL3073, ZL3642, ZL3648, ZL3661, ZL3673, ZL4373, ZL4385

Double-layer product specifications: 2ZL1848, 2ZL1861, 2ZL2448, 2ZL2461, 2ZL3048, 2ZL3061,

2ZL3073, 2ZL3648, 2ZL3661, 2ZL3673, 2ZL4361, 2ZL4373, 2ZL4385

Three layer product specifications: 3ZL2461, 3ZL3061, 3ZL3073, 3ZL3673

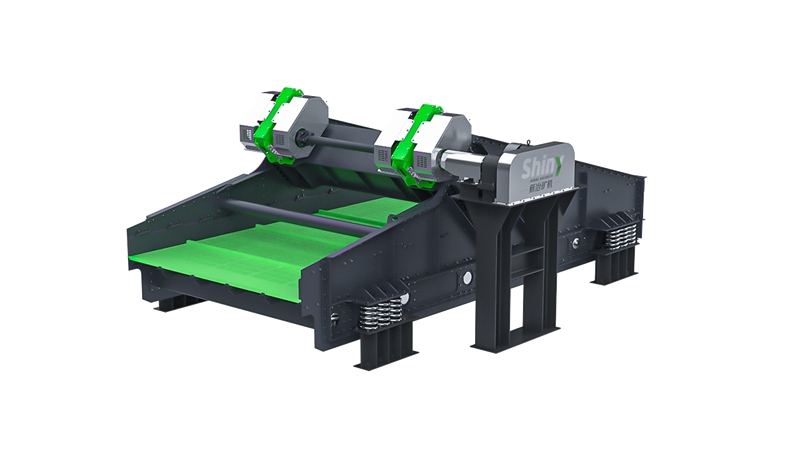

Shiny Mining Machinery vibrating screen introduction

The application of equal thickness screening principle and linear vibration theory, the use of advanced design concepts and finite element force analysis and calculation means, equipped with gantry machining center, vertical machining center, horizontal machining center and other CNC processing equipment, testing equipment, has the domestic advanced vibrating screen test and detection system.

The design and manufacture of Shiny Mining Machinery vibrating screen conforms to the requirements of GB mechanical design standard, IEC international electrical standard, JB/T9022-1999[Vibrating screen design Code] and JB/T5496-2004[General Technical conditions for vibrating screen manufacturing] and relevant coal preparation machinery industry standards.

The vibrating screen of Shiny Mining Machinery is mainly used for coal classification, desliming, dehydration, crushing and screening of metal mines, grading of sand and aggregate, and also suitable for screening and grading of other minerals.

The technical characteristics and advantages of new mining machine vibrating screen

Simple and compact structure, high stiffness, high strength, balanced force distribution, large safety factor

The vibration parameters are set reasonably to avoid the natural frequencies of the screen body at all levels and reduce the impact of resonance

Long service life, screen body service life of up to 10 years, exciter service life of more than 60,000 hours

Light weight, low power consumption, high vibration intensity (9-12mm), high screening efficiency (>95%)

Low noise, noise level below 85 decibels, smooth operation

The working system of the whole machine is S1, which ensures stable and continuous work for 24 hours

The FFT professional frequency analyzer was used for frequency response and dynamic analysis

The variety is complete and can fully meet the screening process requirements of different material characteristics and processing capacity

The screen machine is simple to operate and maintain, safe to use, cost-effective, sufficient spare parts, timely and thoughtful service